Grease and starch separators

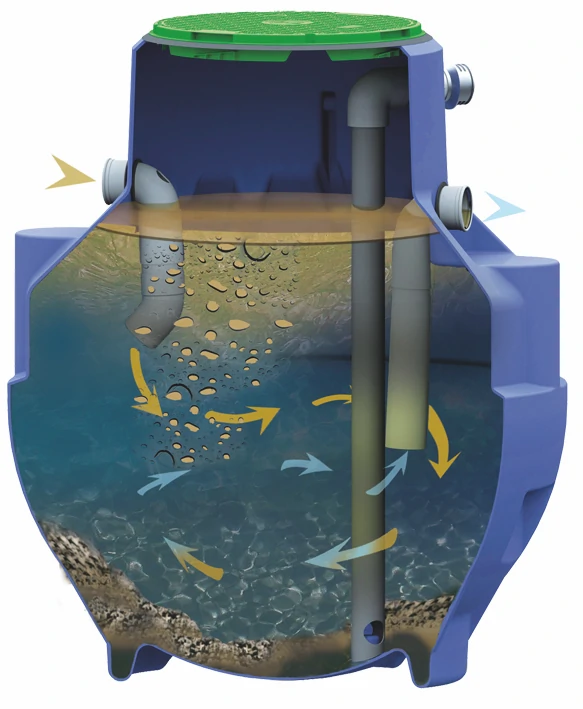

Grease and/or starch separators are based on a simple principle: the difference in density between the elements present in wastewater. Fats and oils, which are lighter than water, rise to the surface, while heavier solids settle to the bottom. The water flows naturally between the two layers.