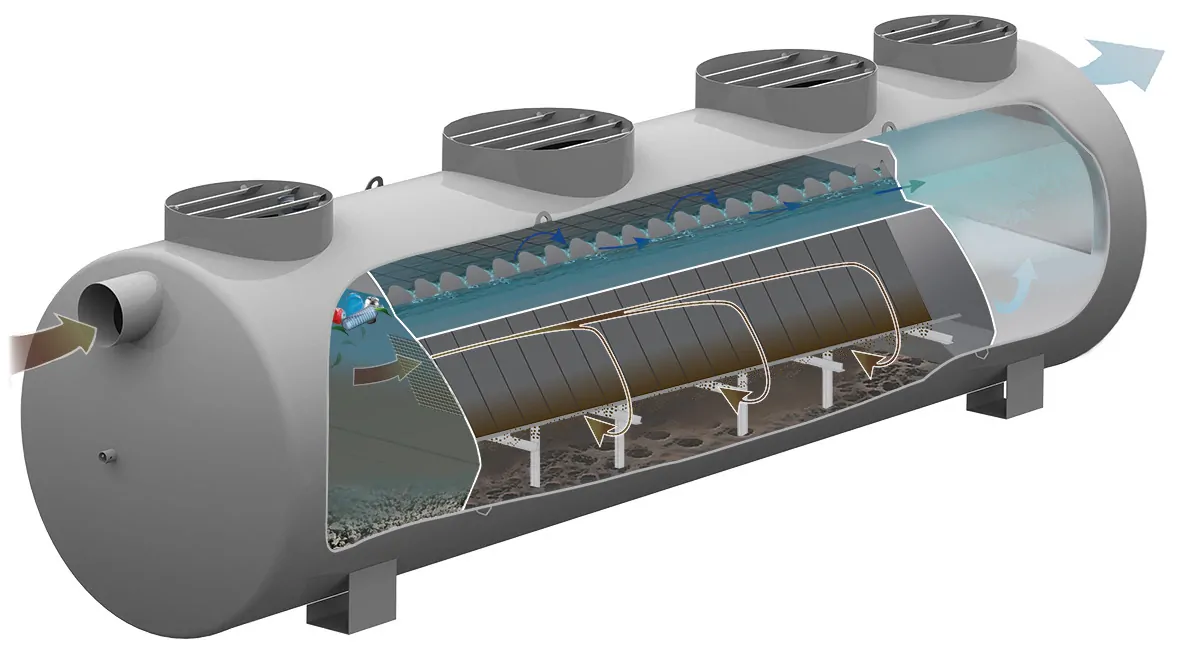

Storm water treatment units

Techneau has developed a range of particle separators for use in open parking lots and on roads and freeways, where pollution is mainly characterized by suspended solids, to which the majority (80%) of pollutants are bound. These structures also have the capacity to intercept chronic and accidental pollution from light liquids.